7

APPLICATIONS

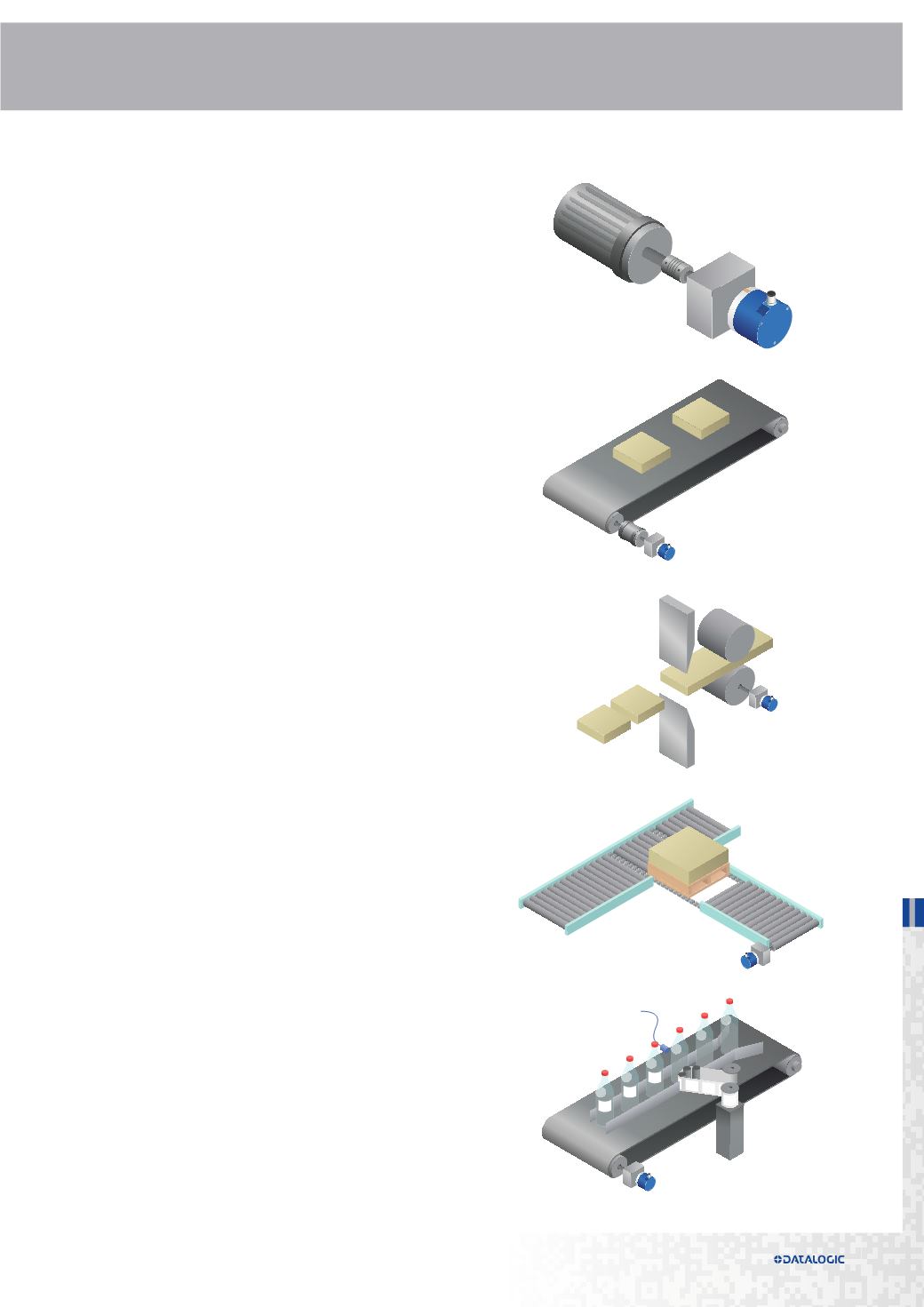

Motion control

is the most common application, the

encoder is mounted directly to the end of a motor via

a shaft and provides feedback to a drive to verify that

the speed and direction is correct

Web speed or tension control

is another application

in which an encoder is mounted to, so that any

unevenness in the rotating speed of the tension roller

is fed to a controller to maintain an even tension

Length measurement applications

use an encoder

mounted on a wheel, in order to convert a linear

movement into a rotationangle, or number of rotations,

so providing a length measurement to control cutting,

folding or other operations

Conveying

is another common industry application

where encoders are used to control speed and position

of amotor or intermediate axle shafts along conveyors.

Encoder information is synchronized, for example, to

control barcode scanners or label printers

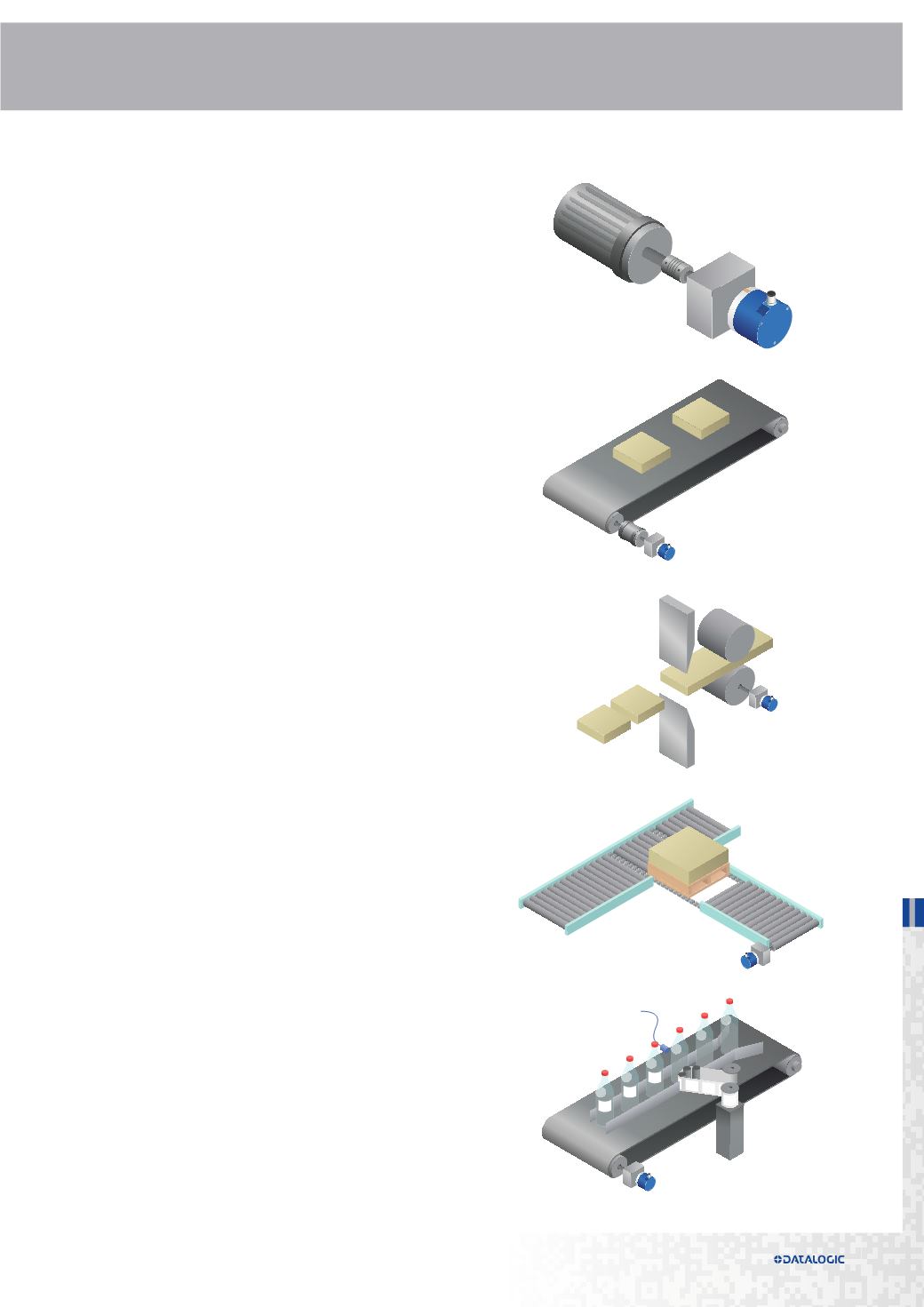

Automated packaging machinery

has many axes of

high-speed rotary motion that require feedback for

motion control, hence, the frequent need of encoders

for speed or position feedback, length measurement

and positioning applications

Illustrazioni Encoder 1

Illustrazioni Encoder 3

Illustrazioni Encoder 5

Illustrazioni Encoder 2

Illustrazioni Encoder 4