11

1

S1

F1

P1

P1

PL

r

a

b

c

d

e

P1

P1

P2

P2

P2

P2

F1

F2

F2

S2

1

S1

F1

P1

P1

PL

r

a

b

c

d

e

P1

P1

P2

P2

P2

P2

F1

F2

F2

S2

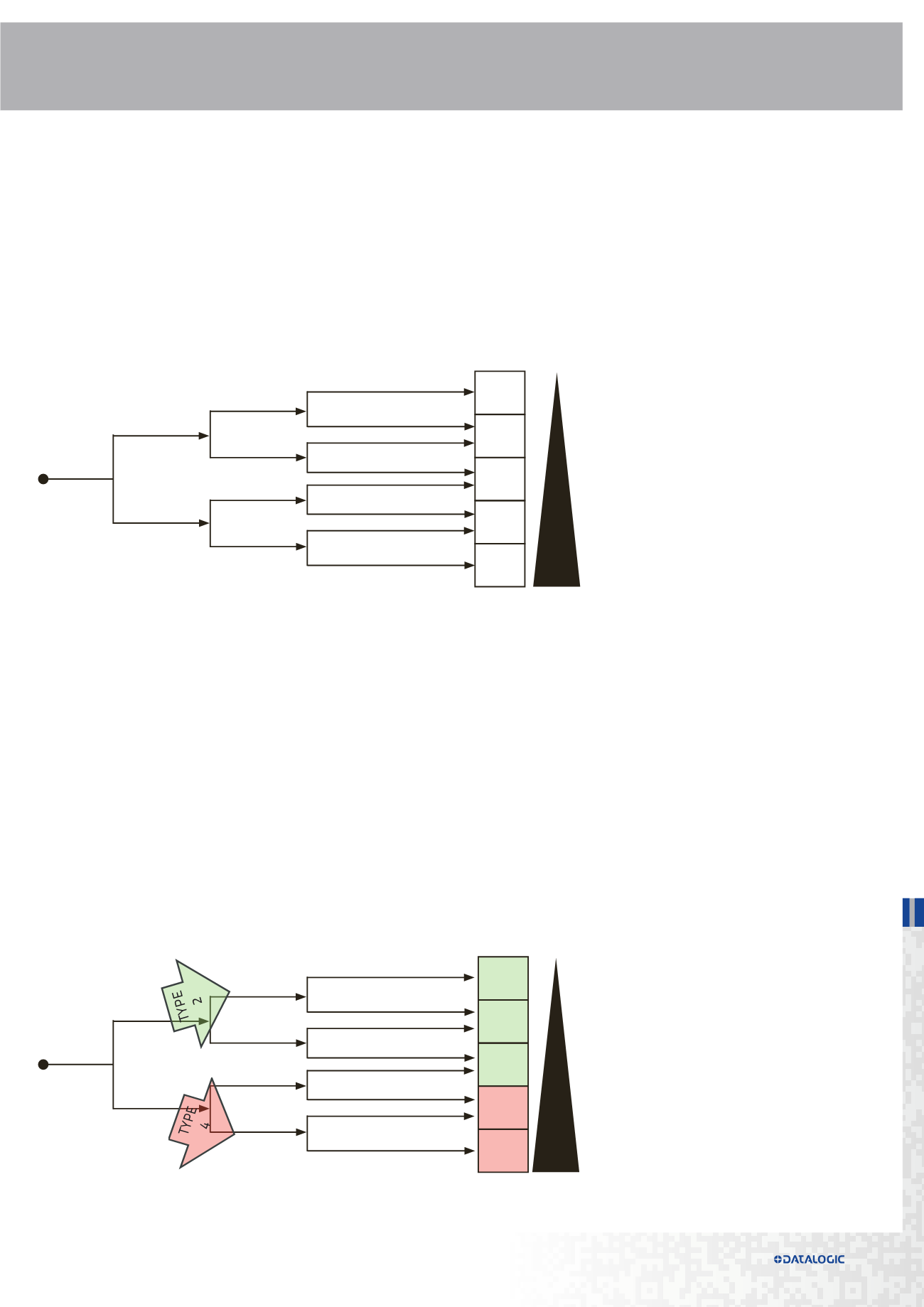

1. Performance Level (PL) and required Performance Level (PLr)

Performance level is one of five discrete levels (a, b, c, d, e) that specify the ability of the safety-related part of a control

system to perform a specific safety function. The performance level depends on the system design, the reliability of

components used, the diagnostic coverage of dangerous faults , and on the ability of the safety parts to avoid common

cause and systematic faults.

The minimum required Performance Level (PLr) to reduce a risk is determined by following the diagram in fig. 1, which

takes into account three factors: the severity of injury, the frequency of exposure to hazard, and the possibility to avoid

the hazard. Performance level and its calculation methods are described in EN ISO 13849-1.

SELECTION GUIDE

LOW

HIGH

Risk parameters

S severity of injury

S1 slight (normally reversible injury)

S2 serious (normally irreversible injury or death)

F frequency and/or exposure to hazard

F1 seldom-to-less-often and/or exposure time is short

F2 frequent-to-continuous and/or exposure time is long

P possibility of avoiding hazard or limiting harm

P1 possible under specific conditions

P2 scarcely possible

Fig. 1 Required Performance Level

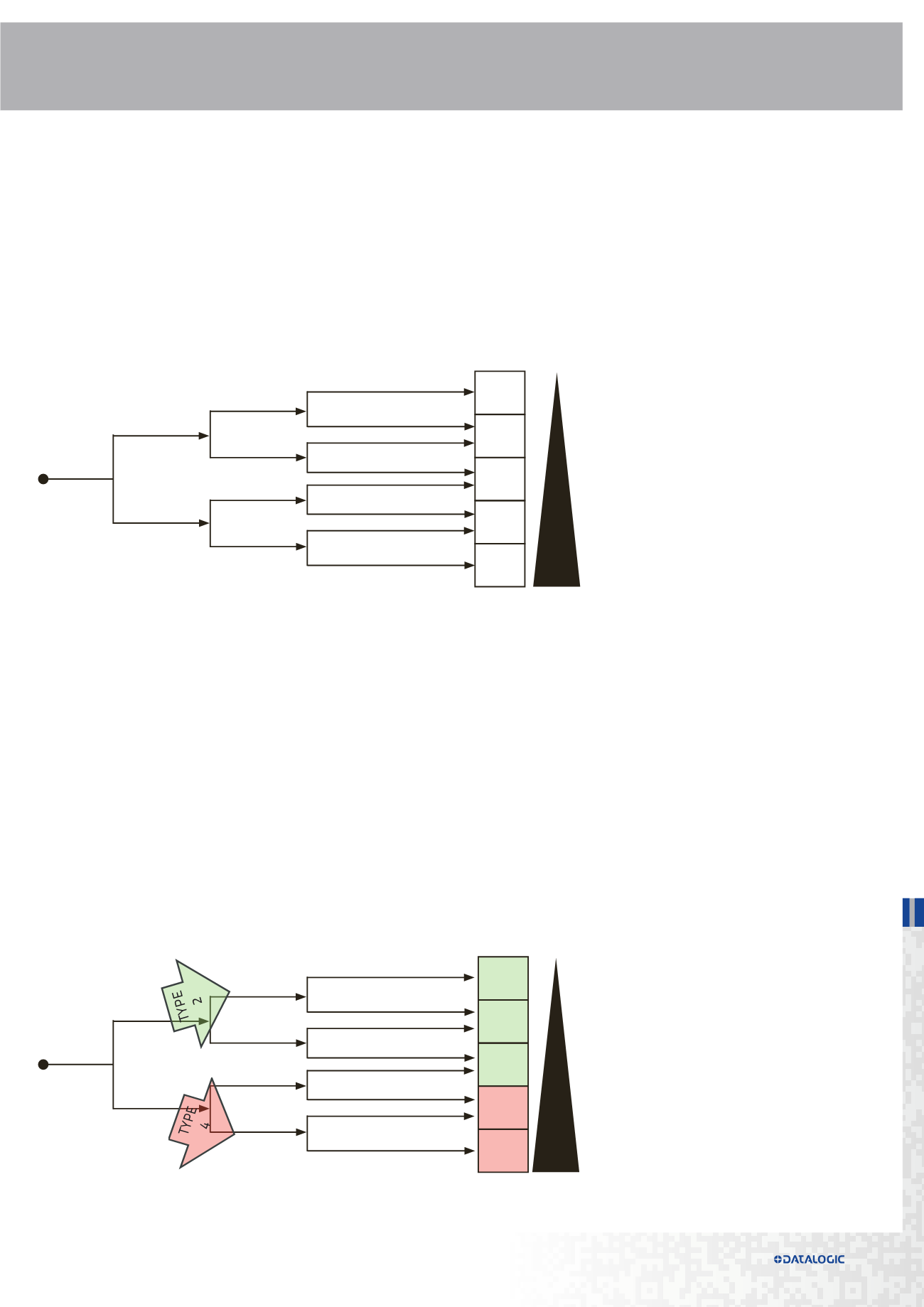

2. Type

Safety sensors whose function is to detect the interruption of beams by an object are called Active Optoelectronic

Protective Devices (AOPD). AOPDs are classified in two Types (Type 2 and Type 4) depending on their design and optical

performance.

The optical performance is dependent on the maximum limit of the effective aperture angle (EAA), that is -/+5° for Type

2, and -/+ 2.5° for Type 4. A lower EAA results in a more focused beam.

Type and Performance Level are directly correlated: Type 2 Sensors must reach at least PL c, and Type 4 Sensors must

reach at least PL e.

Conversely, the maximum PL that can be reached for a safety function that includes the use of a Type 2 AOPD is PL c,

while for a Type 4 AOPD, the maximum is PL e.

Based on these considerations, to reduce the highest risks on machines, Type 4 AOPDs should be used (see Fig. 2).

Active optoelectronic protective devices and corresponding Types are described in IEC 61496-1 and IEC 61496-2.

LOW

HIGH

Risk parameters

S severity of injury

S1 slight (normally reversible injury)

S2 serious (normally irreversible injury or death)

F frequency and/or exposure to hazard

F1 seldom-to-less-often and/or exposure time is short

F2 frequent-to-continuous and/or exposure time is long

P possibility of avoiding hazard or limiting harm

P1 possible under specific conditions

P2 scarcely possible

Key

1 starting point for evaluation of safety function's

contribution to risk reduction

L low contribution to risk reduction

H high contribution to risk reduction

PLr required performance level

Fig. 2 AOPD Type and Performance Level