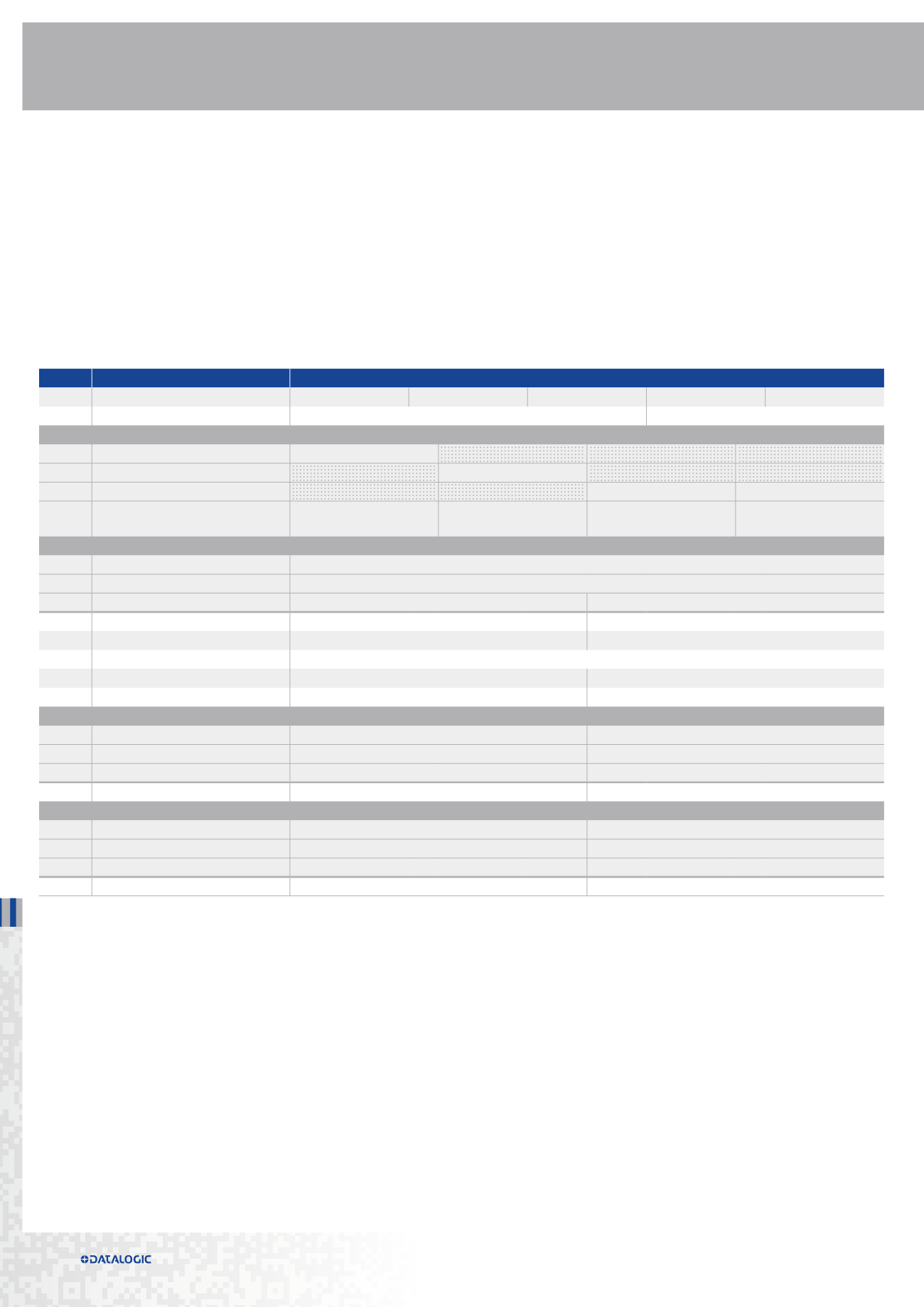

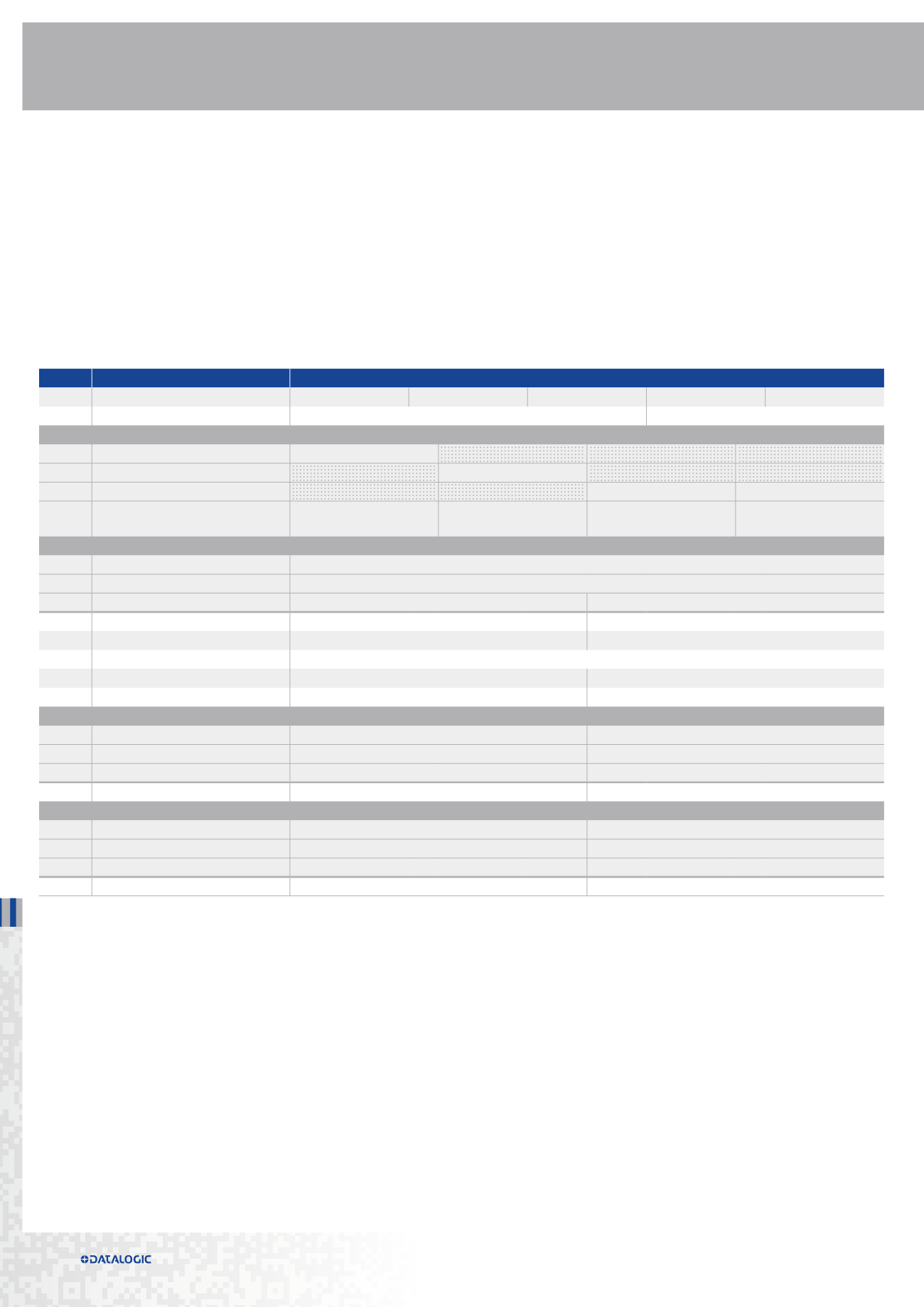

10

SELECTION GUIDE

The selection of safety sensors for use in machinery is part of the overall risk reduction process, which starts with the

analysis and evaluation of all possible risks the machine presents and ends with the validation and testing of the safety

system. The sensors chosen should fulfill any safety requirements specific to the machine they will be mounted on. If

there are no machine-specific requirements, the safety system should be designed to comply with all general safety

and health standards. The overall system design dictates the parameters the safety sensors must meet. The following

list of parameters and functions related to safety sensors can serve as a checklist to help in the selection process.

SELECTION GUIDE

Number

DEFINITION

VALUES

1

Performance level required

a

b

c

d

e

2

Type

2

4

3

Detection capability

Finger protection

14 mm

Hand protection

30 mm

Arm protection/Presence

50 mm

90 mm

Body protection

2 beams

500 mm

3 beams

800 mm

4 beams

900 mm

4 beams

1200 mm

4

Detection zone

Height

from 150 mm to 1800 mm

Operating range

from 0.2 m to 60 m

Zero dead zone

yes

no

5

Retroreflective light curtains

yes

no

6

Cascading

yes

no

7

Response time

from 8 ms to 33 ms

8

Manual or automatic restart

Manual

Automatic

9

External Device Monitoring (EDM)

yes

no

10

Muting

Type of muting

T

L

Integrated muting lamp

yes

no

Partial muting

yes

no

11

Override

yes

no

12

Blanking

Fixed Blanking

yes

no

Floating Blanking

yes

no

Reduced resolution

yes

no

13

Software configuration

yes

no